Inconel 625 Threaded Fittings

Nickel Alloy 625 Threaded Fittings, Alloy 625 Forged Threaded Pipe Nipple, Inconel Alloy 625 Threaded Cross, 625 Inconel Threaded Coupling, Inconel 625 Forged Threaded Tee Manufacturer in India, Alloy 625 Threaded Elbow, Alloy 625 Screwed Fittings Stockist In India.

Aashish Metal & Alloys is a standard manufacturer and trader of Inconel 625 Threaded Fittings, which offers top corrosion resistance and oxidation resistance.

Meanwhile, the including up of Titanium stabilizes in competition to the configuration of Chromium Carbide in warmth that degrees among 800 ranges Fahrenheit to 1500 ranges Fahrenheit. Inconel Alloy UNS N06625 Threaded Elbow Fittings preferentially counters within the organisation of carbon within the metallic and averts precipitation of chromium carbides on the grain limits. As an end result keeping corrosion-resistant traits in such fittings via way of means of thwarting discount of chromium close to the grain confines at some stage in revelation inside vast temperature variety.

- Inconel 625 Threaded Fittings Specifications

- Inconel 625 Threaded Fittings Equivalent Grades

- Inconel 625 Threaded Fittings Quality and Test reports

- Inconel 625 Threaded Fittings International Standards

- Related Types Of Inconel 625 Threaded Fittings

- ASTM B564 Inconel 625 Threaded Forged Fittings Dimensions Chart

- Inconel 625 Threaded Fittings Pressure Rating

- Chemical Composition

- Mechanical Properties

- Inconel 625 Threaded Fittings price list

- We supply of variety Inconel 625 Threaded Fittings

- Application Of Inconel 625 Threaded Fittings

ANSI B16.11 Inconel 625 Threaded Union, 2.4856 High Pressure Threaded Fittings, Alloy 625 Threaded Pipe Cap, ASTM B564 Inconel 625 Threaded 90 degree Elbow, Inconel® Alloy 625 Forged Threaded Reducing Insert, Alloy 625 45 Deg Threaded Elbow, Inconel® Alloy 625 Threaded Plug, UNS N06625 Bushing Suppliers in Mumbai, India.

They have a few tremendous capabilities love it reacts properly to hardening via way of means of cold working, and feature extremely good welding traits. They have top corrosion resistance in a huge type of corrosive media, have High creep and pressure rupture houses, etc. Inconel Alloy WNR 2.4856 Threaded 45-Degree Elbow Fittings are getting used for various applications which include in Aircraft exhaust stacks, Chemical processing system, Welded system, etc. They are as properly utilized in High temperature chemical manner system, Fabrication enterprise, and more. It is a miles and huge used as metallic, wherein its additives are being heated inside carbide-precipitation temperature, and is likewise uncovered to corrosive environment.

It has a few extremely good welding houses, and post-weld annealing isn’t always required in fashionable for to reinstate its top overall performance in an in depth variety of corrosive forms. The addition of titanium facilitates to enhance its welding traits and the excessive temperature houses of the metallic. Under a bit cyclic shape withinside the route of 2000 Deg F, it’s far an austenitic warmth resistant alloy via way of means of method of getting top resistance to oxidation. Nickel Alloy 625 Threaded 90-Degree Elbow also are utilized in Heat exchangers, Jet engine parts, Aircraft enterprise, Refinery enterprise system Oil refineries, Manifolds, etc. However, it consists of the including up of Titanium which finally makes such fittings an amazing desire for long-lasting increased temperature applications.

Inconel 625 Threaded Fittings Specifications

| Dimensions | ASTM B564 / ASME SB564 |

|---|---|

| Standard | ASME 16.11, MSS SP-79, 83, 95, 97, BS 3799 |

| Size | 1/8″ NB to 4″ NB Screwed-Threaded |

| Class | 2000lb/ 3000lb/ 6000lbs |

| From | 90º Elbows, 45º Elbows, Tees, Cross, Couplings, Reducers, Inserts, Caps, Nipples, Unions, Equal Tees & Reducing Tees, Plugs. |

Inconel 625 Threaded Fittings Equivalent Grades

| STANDARD | UNS | WERKSTOFF NR. | AFNOR | EN | JIS | BS | GOST | OR |

|---|---|---|---|---|---|---|---|---|

| Inconel 625 | N06625 | 2.4856 | NC22DNB4M | NiCr22Mo9Nb | NCF 625 | NA 21 | ХН75МБТЮ | ЭИ602 |

Inconel 625 Threaded Fittings Quality and Test reports

- Third Party Inspection

- EN 10204/3.1B

- 100% Radiography Test

- Raw Materials Certificate

- Mill test

Inconel 625 Threaded Fittings International Standards

| American Steel Threaded Fittings Standard | |

| Standard Code | Standard Name |

| ANSI ASME SA-182 | Forged fittings |

| ANSI ASME B16.11 | Socket-welding and Threaded forged fittings |

| MSS SP-79 | Socket-welding reducing Inserts |

| MSS SP-83 | Class 3000 steel socket-welding and threaded unions |

| MSS SP-95 | Swaged nipples and round plugs |

| MSS SP-97 | SW,TH and BW ends for integrally reinforced forged branch outlet |

We Supplied a Comprehensive Range Of Inconel 625 Threaded Fittings

Related Types Of Inconel 625 Threaded Fittings

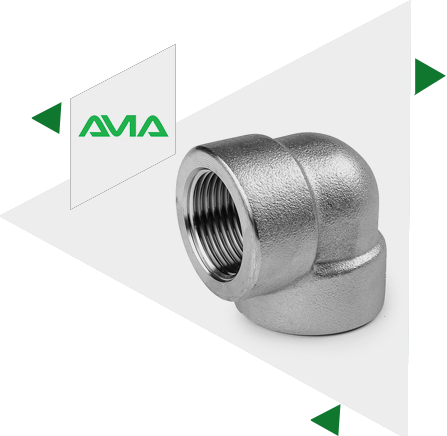

Inconel 625 Threaded Elbow

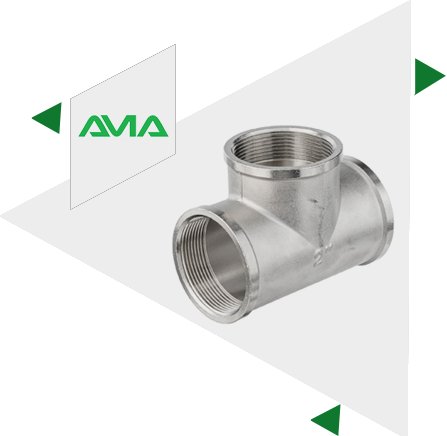

Inconel 625 Threaded Tee

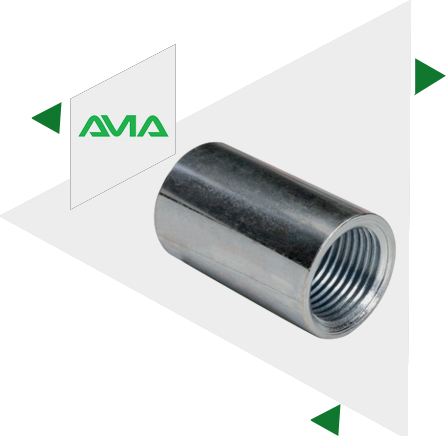

Inconel 625 Threaded Full Coupling

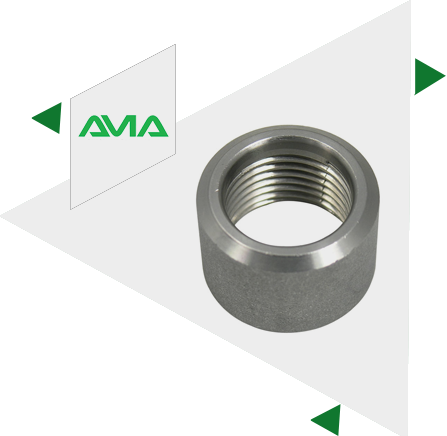

Inconel 625 Threaded Half Coupling

Inconel 625 Threaded Cross

Inconel 625 Threaded Union

Inconel 625 Threaded Pipe Cap

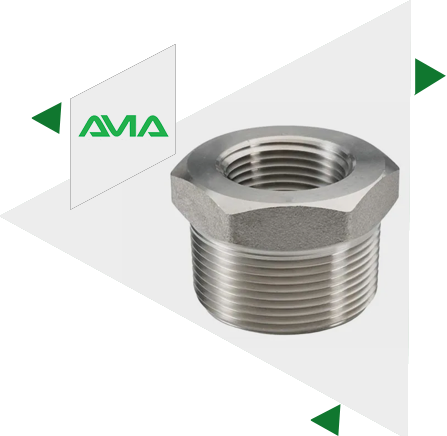

Inconel 625 Bushing

Inconel 625 Threaded Plug

Inconel 625 Threaded Hex Plug

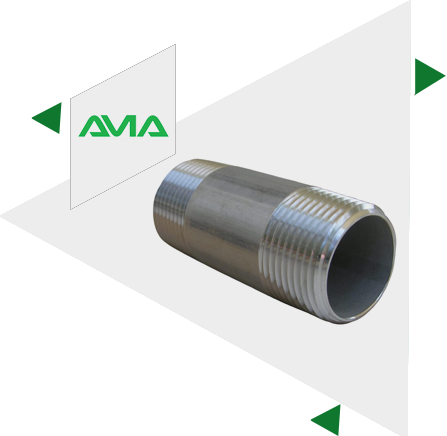

Inconel 625 Threaded Pipe Nipple

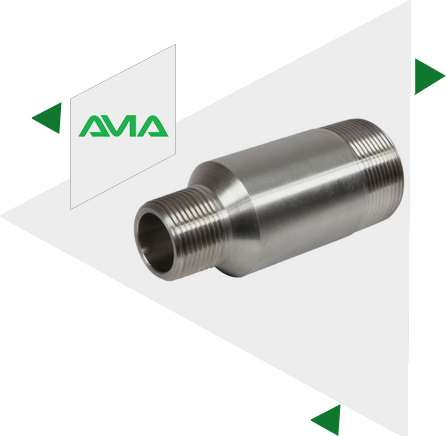

Inconel 625 Threaded Swage Nipple

ASTM B564 Inconel 625 Threaded Forged Fittings Dimensions Chart

| DN | NPS | Center to End NPT Elbow, NPT Tee, NPT Cross A |

Center to End 45 Deg Elbow C |

O.D. of Band H |

Min. Wall Thick. G |

Length of Thread. Minimum (1) |

|||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Class 2000 | Class 3000 | Class 6000 | Class 2000 | Class 3000 | Class 6000 | Class 2000 | Class 3000 | Class 6000 | Class 2000 | Class 3000 | Class 6000 | B | L2 | ||

| 6 | 1/8 | 21 | 21 | 25 | 17 | 17 | 19 | 22 | 22 | 25 | 3.18 | 3.18 | 6.35 | 6.4 | 6.7 |

| 8 | 1/4 | 21 | 25 | 28 | 17 | 19 | 22 | 22 | 25 | 33 | 3.18 | 3.30 | 6.60 | 8.1 | 10.2 |

| 10 | 3/8 | 25 | 28 | 33 | 19 | 22 | 25 | 25 | 33 | 38 | 3.18 | 3.51 | 6.98 | 9.1 | 10.4 |

| 15 | 1/2 | 28 | 33 | 38 | 22 | 25 | 28 | 33 | 38 | 46 | 3.18 | 4.09 | 8.15 | 10.9 | 13.6 |

| 20 | 3/4 | 33 | 38 | 44 | 25 | 28 | 33 | 38 | 46 | 56 | 3.18 | 4.32 | 8.53 | 12.7 | 13.9 |

| 25 | 1 | 38 | 44 | 51 | 28 | 33 | 35 | 46 | 56 | 62 | 3.68 | 4.98 | 9.93 | 14.7 | 17.3 |

| 32 | 1-1/4 | 44 | 51 | 60 | 33 | 35 | 43 | 56 | 62 | 75 | 3.89 | 5.28 | 10.59 | 17.0 | 18.0 |

| 40 | 1-1/2 | 51 | 60 | 64 | 35 | 43 | 44 | 62 | 75 | 84 | 4.01 | 5.56 | 11.07 | 17.8 | 18.4 |

| 50 | 2 | 60 | 64 | 83 | 43 | 44 | 52 | 75 | 86 | 102 | 4.27 | 7.14 | 12.09 | 19.0 | 19.2 |

| 65 | 2-1/2 | 76 | 83 | 95 | 52 | 52 | 64 | 92 | 102 | 121 | 5.61 | 7.65 | 15.29 | 23.6 | 28.9 |

| 85 | 3 | 86 | 95 | 106 | 64 | 64 | 79 | 109 | 121 | 146 | 5.99 | 8.84 | 16.64 | 25.9 | 30.5 |

| 100 | 4 | 106 | 114 | 114 | 79 | 79 | 79 | 146 | 152 | 152 | 6.55 | 11.18 | 18.67 | 27.7 | 33.0 |

| DN | NPS | End to End Couplings W |

End to End Caps P |

O.D. D | End Wall Thick. G Minimum |

Length of Thread. Minimum (1) |

||||

|---|---|---|---|---|---|---|---|---|---|---|

| Class 3000&Class 6000 | Class 3000 | Class 6000 | Class 3000 | Class 6000 | Class 3000 | Class 6000 | B | L2 | ||

| 6 | 1/8 | 32 | 19 | … | 16 | 22 | 4.8 | … | 6.4 | 6.7 |

| 8 | 1/4 | 35 | 25 | 27 | 19 | 25 | 4.8 | 6.4 | 8.1 | 10.2 |

| 10 | 3/8 | 38 | 25 | 27 | 22 | 32 | 4.8 | 6.4 | 9.1 | 10.4 |

| 15 | 1/2 | 48 | 32 | 33 | 28 | 38 | 6.4 | 7.9 | 10.9 | 13.6 |

| 20 | 3/4 | 51 | 37 | 38 | 35 | 44 | 6.4 | 7.9 | 12.7 | 13.9 |

| 25 | 1 | 60 | 41 | 43 | 44 | 57 | 9.7 | 11.2 | 14.7 | 17.3 |

| 32 | 1-1/4 | 67 | 44 | 46 | 57 | 64 | 9.7 | 11.2 | 17.0 | 18.0 |

| 40 | 1-1/2 | 79 | 44 | 48 | 64 | 76 | 11.2 | 12.7 | 17.8 | 18.4 |

| 50 | 2 | 86 | 48 | 51 | 76 | 92 | 12.7 | 15.7 | 19.0 | 19.2 |

| 65 | 2-1/2 | 92 | 60 | 64 | 92 | 108 | 15.7 | 19.0 | 23.6 | 28.9 |

| 80 | 3 | 108 | 65 | 68 | 108 | 127 | 19.0 | 22.4 | 25.9 | 30.5 |

| 100 | 4 | 121 | 68 | 75 | 140 | 159 | 22.4 | 28.4 | 27.7 | 33.0 |

Inconel 625 Threaded Fittings Pressure Rating

| ASME B16.11 Pressure-Temperature | |||||

|---|---|---|---|---|---|

| Temperature | Class | ||||

| 150 | 300 | ||||

| 1/4 – 1 inch. | 1 1/4 – 2 inch. | 2 1/2 – 3 inch. | |||

| (oF) | (oC) | ||||

| -20 to 150 | -29 to 66 | 300 | 2000 | 1500 | 1000 |

| 200 | 93 | 265 | 1785 | 1350 | 910 |

| 250 | 121 | 225 | 1575 | 1200 | 825 |

| 300 | 149 | 185 | 1360 | 1050 | 735 |

| 350 | 177 | 150 | 1150 | 900 | 650 |

| 400 | 204 | – | 935 | 750 | 560 |

| 450 | 232 | – | 725 | 600 | 475 |

| 500 | 260 | – | 510 | 450 | 385 |

| 550 | 288 | – | 300 | 300 | 300 |

We Keep Bulk Stock Of Inconel 625 Forged Threaded Fittings At Our Stockyard, Contact Us For Free Sample & Stock List.

Chemical Composition

| Grade | C | Mn | Si | S | Al | Fe | Ti | Cr2 | Mo | Nb + Ta | Ni |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 625 | 0.10 | 0.50 | 0.50 | 0.015 | 0.40 | 5.0 | 0.40 | 20.0-23.0 | 8.0-10.0 | 3.15–4.15 | 58.0 min |

Mechanical Properties

| Grade | Density | Melting Point | Yield Strength (0.2%Offset) | Tensile Strength | Elongation |

|---|---|---|---|---|---|

| 625 | 8.4 g/cm3 | 1350 °C (2460 °F) | Psi – 75,000 , MPa – 517 | Psi – 1,35,000 , MPa -930 | 42.5 % |

For Inconel 625 Threaded Fittings price list

Request the latest Inconel 625 Threaded Fittings List. Please click on the request a quote button or click here to request the updated price list and ready stock information along with your requirement. Aashish Metal & Alloys maintains a stock of all standard items and can export them at best price for 625 Inconel Screwed Fittings .

We supply of variety Inconel 625 Threaded Fittings

Aashish Metal & Alloys is a Highly Acclaimed Manufacturer & suppliers of Inconel 625 Threaded Forged Fittings offering all varieties in all types of 625 Inconel in all sizes, with more then 52 countries worldwide.

| Inconel 625 Threaded Fittings | Inconel 625 Forged Threaded Fittings |

| Alloy 625 High Pressure Threaded Fittings | Inconel 625 Threaded 45 deg. Elbow |

| UNS N06625 Screwed Fittings | Inconel 625 Forged Threaded Tee |

| Inconel 625 NPT Threaded Fittings | Inconel® Alloy 625 BSP Threaded Elbow |

| Alloy 625 Threaded 45 Deg Elbow Suppliers | Inconel 625 90 Degree Threaded Elbow |

| Inconel 625 Threaded End Cap Dealer | Inconel® Alloy 625 Threaded Half Coupling Exporter |

| Inconel Alloy 625 Threaded Tee Stockholder | Alloy 625 Threaded Reducing Tee Distributors |

| Inconel® Alloy 625 Threaded Equal Cross | ANSI B16.11 Inconel 625 Threaded Pipe Cap |

| Inconel® Alloy 625 Threaded Unequal Cross | Alloy 625 High Pressure Screwed Fittings Manufacturer |

| 625 Inconel Threaded Coupling | Alloy 625 Threaded Reducing Couplings |

| Inconel® Alloy 625 Threaded Plug | 625 Inconel Swage Nipple |

| DIN 2.4856 Forged Threaded Tee | Nickel Alloy 625 Threaded Equal Cross |

| Inconel 625 Threaded Full Coupling | Inconel® Alloy 625 Forged Threaded Union |

| Inconel 625 Bushing | Alloy 625 Threaded Pipe Nipple |

| Inconel 625 Bushing | Inconel Alloy 625 Threaded Pipe Nipple |

| Alloy 625 Hex Head Bushing | Inconel® Alloy 625 Hex Head Plug |

| Alloy 625 Threaded Equal Tee | Inconel 625 Threaded Half Coupling Stockist |

| ASTM B564 Inconel 625 Threaded Boss | ASME SB564 Alloy 625 Threaded Pipe Cap |

| Inconel® Alloy 625 Threaded Hex Plug | Inconel® Alloy 625 NPT Threaded Street Elbow |

Application Of Inconel 625 Threaded Fittings

Application Industry

For More Information About Inconel 625 Threaded Fittings please call +91-22-66362223 / 66394926 or send an email to [email protected]

Export Country

MIDDLE EAST Saudi Arabia | AFRICA Nigeria NORTH AMERICA Usa | EUROPE Russia | ASIA India SOUTH AMERICA Argentina |

Products

- Stainless Steel

- Duplex & Super Duplex

- Nickel Alloy

- Monel

- Inconel

- Hastelloy

- Alloy 20

- Titanium

- Copper Nickel

- Alloy Steel

- Carbon Steel

- Beryllium Copper

- Bimetal

Special Products

PRODUCT RANGE

Please feel free to contact us. We will get back to you with 2 business days. Or just call us now.