Mistakes of Selecting Types of Stainless Steel Flanges

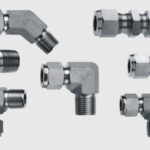

Any Product or Business must use the proper stainless steel flanges in order to function properly. The flange must perfectly fit into the pipe joints for proper operation. Inappropriate flange selection can have a big impact on your application and cost you a lot of money.

However, compared to other metals, scratches and dents are more noticeable due to the highly polished surface. Additionally, faults are simple to make because of the material’s vulnerability to harm.

When handling stainless steel Flanges, avoid these typical mistakes.

Distortion

Stainless steel Flange is prone to deformation during welding techniques because of its poor heat conductivity and quick expansion rate. Use the least amount of amperage possible without compromising the weld’s quality to prevent deformation. To avoid distortion and hold the workpiece firmly in place while tack welding, you should also manage the interpass temperatures.

Surface Compounds Are Being Introduced

Working with Hydraulic SAE Flanges exposes you to the possibility of contaminating the surface with various substances. Iron filings and other impurities may even make their way to the metal’s surface while it is being fabricated. When handling stainless steel flanges, the handler’s hands may have grease, chalk, or other impurities on them. These pollutants could lead to localised corrosion.

To prevent surface contamination, it would be ideal to use an abrasive that is specifically made for stainless steel abrasive particles, blending, and deburring. Mixing stainless steel abrasives with other metal abrasives is not recommended. Instead, keep stainless steel in its original packaging for as long as feasible and store it apart from other metals.

Inadequate Cleaning

Because scratches appear so quickly on stainless steel, very specific cleaning techniques are needed. Stainless steel flanges shouldn’t be scrubbed too vigorously or cleaned with abrasive cleaners. Unattractive water spots may develop on stainless steel flanges if they are not properly rinsed after cleaning. Using cleansers with chlorine or bleach in them will damage stainless steel as well. Clean a clean microfiber and warm water should be used to clean hydraulic SAE flanges. After gently washing the stainless steel, give it a thorough rinse. After rinsing, dry the surface with a soft cloth to prevent water stains.

Allowing the Bolts to Remain Undone

The flange guard bolts frequently need to be loosened for maintenance or repairs. You must make sure you take the necessary safeguards to stop this from happening again, even if the unfastened bolts were only left undone for a brief period of time.

A significant accident might happen in a matter of seconds. The simplest way to prevent them is to consistently tighten the nuts on the flange guards. You run the danger of making a mistake and accidentally spraying anything if you leave them undone.

Putting Your Safety in the Hands of Someone Else

It would be great if you took the necessary precautions to avoid endangering anyone else’s safety. Being the owner or manager of the factory, you are the best person to examine the safety standards for your plant or factory.

Therefore, remain vigilant at all times and take no chances. If you assign someone to the work, that person could not be familiar with the broader environment and so be unable to comprehend and manage safety problems.