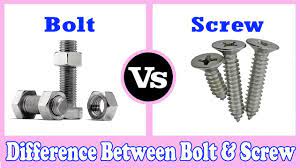

As with so many things in the fastener business, the best answer to the question “What’s the difference between a bolt and a screw?” is “It depends on who you ask.”

Most people have a basic understanding of what a screw and bolts are. However, there are so many different types of bolts and screws that it might be difficult to identify a particular fastener. This page should offer some guidance.

Bolts vs Screw Definitions

Let us begin with a couple of definitions provided by the CBP, as quoted from ANSI-ASME B18.2.1:

Bolt: A bolt is an externally threaded fastener that is designed to be inserted through holes in assembled parts and tightened or released by torqueing a nut.

Screw: A screw is an outwardly threaded fastener that can be placed into holes in constructed parts, mate with a preformed internal thread, or form its own thread, and be tightened or released by torqueing the head.

Bolt vs Screw: Four Main Criteria

The basis of the two aforementioned definitions serves as the basis for the four main criteria. In essence, each of the four criteria seeks to validate a crucial component of a particular definition. A portion can be identified without additional investigation if it blatantly meets any of the four requirements.

Criterion 1 — Bolt

The fastener in question is a bolt if it includes a head or other design element that keeps it from spinning during assembly and requires a nut to be turned in order to tighten. This criterion is an elimination process. Since the purpose of a screw is to be tightened by twisting the head, a bolt must be present if the head cannot be turned.

Criterion Two — Bolt

An externally threaded fastener is a bolt if its intended use calls for a nut to be assembled in order for it to be assembled. It goes without saying that knowledge of the fastener in question’s intended use is necessary to meet this grade.

Criterion Three — Screw

The component is a screw if the fastener in issue has a thread form that prevents it from being put together with a nut. This is another instance of a process of elimination. A part must be a screw if its threads prohibit it from being utilized with a nut, ruling out the possibility that it is a bolt.

Criterion Four — Screw

A fastener is considered to be a screw if its head is made to be torqued into a pre-made or tapped hole. Once more, it can be rather beneficial to understand the intended use of a part. A screw is any component made to be torqued into a tapped hole by the head.

Screw vs. Bolt: Nine Additional Considerations

There are nine additional criteria you might look at if you are unable to identify whether a part satisfies any of the four main requirements. A screw is a type of fastener that meets five of the nine additional requirements.

Generally speaking, bolts have a looser tolerance than screws. The part in question may be more closely matched by comparing its tolerances to industry-standard bolt and screw tolerances if you have access to the item’s blueprint or specification.

Point – To make it easier to enter the hole and engage with the internal thread, the shank’s configuration features a chamfer or other specifically prepared point at the end.

Bearing Surface – When tightening the head, a flat, smooth under-head bearing surface will minimize friction and scoring.

Under Head Fillet Radius – To guarantee correct head seating, the angle at which the head and body meet should be managed.

Head Angularity – To guarantee correct seating, the underhead bearing surface’s squareness with the shank needs to be managed.

Thread Concentricity – The body axis should be the center of the threads.

Thread Length – The thread length should be adequate to fully engage with the tapped hole, measured as the axial length of the complete form threads plus up to two incomplete threads at the beginning of the thread.

Body – To fit into holes with tight tolerances, the body, or unthreaded portion of the shank, needs to be regulated in size and roundness.

Shank Straightness – Any camber or bow in the shank that would make it difficult for it to fit into holes with tight tolerances should be removed.

Length – In order to keep the screw from bottoming out in the hole, the total length needs to be regulated.

Conclusion

Regarding the characteristics that distinguish the difference between bolt and screw, there are nevertheless, a lot of differing viewpoints available. Therefore, if you have a document that is more relevant to your situation and tells you something else, don’t consider this one as gospel.