Alloy Steel F9 Threaded Fittings

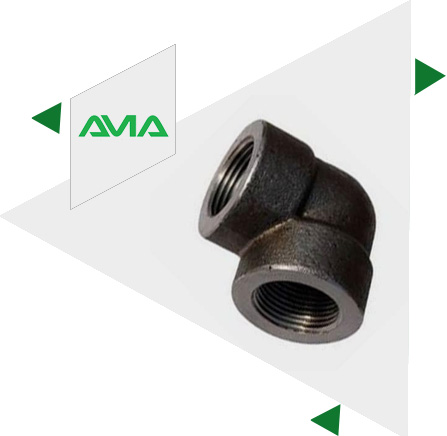

ASTM A182 F9 Threaded Elbow, ASME A182 F9 Threaded Coupling manufacturer In India.

Aashish Metal & Alloys is a popular distributor and exporter of AS F9 Threaded Fittings, which is an alloy evolved for features that entails sulfuric acid.

It is an alloy designed via advanced strength and to face up to carburization and oxidation at excessive temperatures. The excessive nickel content material makes the alloy extraordinarily resistant each to chloride strain-corrosion cracking and to embrittlement from precipitation of sigma period. Alloy Steel F9 Threaded Tee Fittings may be used for various applications including in Furnace device parts, beaming tubes, muffles, warmth deal with trays, manifolds, cracker tubes, meals processing, and so on. It is an austenitic alloy that incorporates advanced ranges of chromium, nickel, copper and molybdenum to provide advanced ranges of corrosion resistance to each pretty oxidizing and comparatively lowering atmospheres.

- Alloy Steel F9 Threaded Fittings Specifications

- Alloy Steel F9 Threaded Fittings Quality and Test reports

- Alloy Steel F9 Threaded Fittings International Standards

- Related Types Of Alloy Steel F9 Threaded Fittings

- Alloy Steel F9 Threaded Forged Fittings Dimensions Chart

- Alloy Steel F9 Threaded Fittings Pressure Rating

- Chemical Composition

- Mechanical Properties

- Alloy Steel F9 Threaded Fittings price list

- We supply of variety Alloy Steel F9 Threaded Fittings

- Application Of Alloy Steel F9 Threaded Fittings

ANSI B16.11 Alloy Steel F9 Threaded Union, ASTM A182 F9 Bushing, ASME A182 F9 45 Deg Threaded Elbow Suppliers in Mumbai, India.

It is a maximum adaptable alloy by way of splendid well-known corrosion resistance and splendid fabricability. It is a maximum creative alloy by way of greater resistance to each localized and uniform corrosion additionally to an intensive variety of combined business chemicals. Alloy Steel F9 Threaded Cross Fittings is a nickel-base fashioned alloy by means of method of getting brilliant resistance to hydrochloric acid in any respect temperatures and concentrations. The addition of inhibited portions of manganese and iron in an uncommon resistance to well-known corrosion and strain cracking, further to impingement and erosion, due to volatile water that incorporates silt flowing and air bubbles at increased velocities.

However, the diminutive iron substance, gives a mind-blowing resistance to wide-ranging corrosion and strain corrosion cracking, and therefore making it extraordinarily best and appropriate for the economic or marine industries. Alloy Steel F9 Threaded Cap Fittings are utilized in a variety of applications including in Seawater piping, Condensers, Exchanger shells, Power plants, etc. It gives chloride and pitting ion corrosion and its copper substance guards it from sulfuric acid. The corrosion resistance additionally unearths its different makes use of in industries like chemical, meals, electricity generation, plastics and pharmaceutical. They are frequently decided on to remedy strain corrosion cracking problems that can possibly take region with stainless.

Alloy Steel F9 Threaded Fittings Specifications

| Dimensions | ASTM A182 / ASME SA182 |

|---|---|

| Standard | ASME 16.11, MSS SP-79, 83, 95, 97, BS 3799 |

| Size | 1/8″ NB to 4″ NB Screwed-Threaded |

| Class | 2000lb/ 3000lb/ 6000lbs |

| From | 90º Elbows, 45º Elbows, Tees, Cross, Couplings, Reducers, Inserts, Caps, Nipples, Unions, Equal Tees & Reducing Tees, Plugs. |

Alloy Steel F9 Threaded Fittings Quality and Test reports

- Third Party Inspection

- EN 10204/3.1B

- 100% Radiography Test

- Raw Materials Certificate

- Mill test

Alloy Steel F9 Threaded Fittings International Standards

| American Steel Threaded Fittings Standard | |

| Standard Code | Standard Name |

| ANSI ASME SA-182 | Forged fittings |

| ANSI ASME B16.11 | Socket-welding and Threaded forged fittings |

| MSS SP-79 | Socket-welding reducing Inserts |

| MSS SP-83 | Class 3000 steel socket-welding and threaded unions |

| MSS SP-95 | Swaged nipples and round plugs |

| MSS SP-97 | SW,TH and BW ends for integrally reinforced forged branch outlet |

We Supplied a Comprehensive Range Of Alloy Steel F9 Threaded Fittings

Related Types Of Alloy Steel F9 Threaded Fittings

Alloy Steel F22 Threaded Elbow

Alloy Steel F22 Threaded Tee

Alloy Steel F22 Threaded Full Coupling

Alloy Steel F22 Threaded Half Coupling

Alloy Steel F22 Threaded Cross

Alloy Steel F22 Threaded Union

Alloy Steel F22 Threaded Pipe Cap

Alloy Steel F22 Bushing

Alloy Steel F22 Threaded Plug

Alloy Steel F22 Threaded Hex Plug

Alloy Steel F22 Threaded Pipe Nipple

Alloy Steel F22 Threaded Swage Nipple

ASTM A182 Alloy Steel F9 Threaded Forged Fittings Dimensions Chart

| DN | NPS | Center to End NPT Elbow, NPT Tee, NPT Cross A |

Center to End 45 Deg Elbow C |

O.D. of Band H |

Min. Wall Thick. G |

Length of Thread. Minimum (1) |

|||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Class 2000 | Class 3000 | Class 6000 | Class 2000 | Class 3000 | Class 6000 | Class 2000 | Class 3000 | Class 6000 | Class 2000 | Class 3000 | Class 6000 | B | L2 | ||

| 6 | 1/8 | 21 | 21 | 25 | 17 | 17 | 19 | 22 | 22 | 25 | 3.18 | 3.18 | 6.35 | 6.4 | 6.7 |

| 8 | 1/4 | 21 | 25 | 28 | 17 | 19 | 22 | 22 | 25 | 33 | 3.18 | 3.30 | 6.60 | 8.1 | 10.2 |

| 10 | 3/8 | 25 | 28 | 33 | 19 | 22 | 25 | 25 | 33 | 38 | 3.18 | 3.51 | 6.98 | 9.1 | 10.4 |

| 15 | 1/2 | 28 | 33 | 38 | 22 | 25 | 28 | 33 | 38 | 46 | 3.18 | 4.09 | 8.15 | 10.9 | 13.6 |

| 20 | 3/4 | 33 | 38 | 44 | 25 | 28 | 33 | 38 | 46 | 56 | 3.18 | 4.32 | 8.53 | 12.7 | 13.9 |

| 25 | 1 | 38 | 44 | 51 | 28 | 33 | 35 | 46 | 56 | 62 | 3.68 | 4.98 | 9.93 | 14.7 | 17.3 |

| 32 | 1-1/4 | 44 | 51 | 60 | 33 | 35 | 43 | 56 | 62 | 75 | 3.89 | 5.28 | 10.59 | 17.0 | 18.0 |

| 40 | 1-1/2 | 51 | 60 | 64 | 35 | 43 | 44 | 62 | 75 | 84 | 4.01 | 5.56 | 11.07 | 17.8 | 18.4 |

| 50 | 2 | 60 | 64 | 83 | 43 | 44 | 52 | 75 | 86 | 102 | 4.27 | 7.14 | 12.09 | 19.0 | 19.2 |

| 65 | 2-1/2 | 76 | 83 | 95 | 52 | 52 | 64 | 92 | 102 | 121 | 5.61 | 7.65 | 15.29 | 23.6 | 28.9 |

| 85 | 3 | 86 | 95 | 106 | 64 | 64 | 79 | 109 | 121 | 146 | 5.99 | 8.84 | 16.64 | 25.9 | 30.5 |

| 100 | 4 | 106 | 114 | 114 | 79 | 79 | 79 | 146 | 152 | 152 | 6.55 | 11.18 | 18.67 | 27.7 | 33.0 |

| DN | NPS | End to End Couplings W |

End to End Caps P |

O.D. D | End Wall Thick. G Minimum |

Length of Thread. Minimum (1) |

||||

|---|---|---|---|---|---|---|---|---|---|---|

| Class 3000&Class 6000 | Class 3000 | Class 6000 | Class 3000 | Class 6000 | Class 3000 | Class 6000 | B | L2 | ||

| 6 | 1/8 | 32 | 19 | … | 16 | 22 | 4.8 | … | 6.4 | 6.7 |

| 8 | 1/4 | 35 | 25 | 27 | 19 | 25 | 4.8 | 6.4 | 8.1 | 10.2 |

| 10 | 3/8 | 38 | 25 | 27 | 22 | 32 | 4.8 | 6.4 | 9.1 | 10.4 |

| 15 | 1/2 | 48 | 32 | 33 | 28 | 38 | 6.4 | 7.9 | 10.9 | 13.6 |

| 20 | 3/4 | 51 | 37 | 38 | 35 | 44 | 6.4 | 7.9 | 12.7 | 13.9 |

| 25 | 1 | 60 | 41 | 43 | 44 | 57 | 9.7 | 11.2 | 14.7 | 17.3 |

| 32 | 1-1/4 | 67 | 44 | 46 | 57 | 64 | 9.7 | 11.2 | 17.0 | 18.0 |

| 40 | 1-1/2 | 79 | 44 | 48 | 64 | 76 | 11.2 | 12.7 | 17.8 | 18.4 |

| 50 | 2 | 86 | 48 | 51 | 76 | 92 | 12.7 | 15.7 | 19.0 | 19.2 |

| 65 | 2-1/2 | 92 | 60 | 64 | 92 | 108 | 15.7 | 19.0 | 23.6 | 28.9 |

| 80 | 3 | 108 | 65 | 68 | 108 | 127 | 19.0 | 22.4 | 25.9 | 30.5 |

| 100 | 4 | 121 | 68 | 75 | 140 | 159 | 22.4 | 28.4 | 27.7 | 33.0 |

Alloy Steel F9 Threaded Fittings Pressure Rating

| ASME B16.11 Pressure-Temperature | |||||

|---|---|---|---|---|---|

| Temperature | Class | ||||

| 150 | 300 | ||||

| 1/4 – 1 inch. | 1 1/4 – 2 inch. | 2 1/2 – 3 inch. | |||

| (oF) | (oC) | ||||

| -20 to 150 | -29 to 66 | 300 | 2000 | 1500 | 1000 |

| 200 | 93 | 265 | 1785 | 1350 | 910 |

| 250 | 121 | 225 | 1575 | 1200 | 825 |

| 300 | 149 | 185 | 1360 | 1050 | 735 |

| 350 | 177 | 150 | 1150 | 900 | 650 |

| 400 | 204 | – | 935 | 750 | 560 |

| 450 | 232 | – | 725 | 600 | 475 |

| 500 | 260 | – | 510 | 450 | 385 |

| 550 | 288 | – | 300 | 300 | 300 |

We Keep Bulk Stock Of F9 Alloy Steel Forged Threaded Fittings At Our Stockyard, Contact Us For Free Sample & Stock List.

Chemical Composition

| Grade | C | Mn | Si | S | P | Cr | Mo |

|---|---|---|---|---|---|---|---|

| A182 F9 | 0.15 | 0.3 – 0.6 | 0.5 – 1 | 0.03 | 0.03 | 8 – 10 | 0.9 – 1.1 |

Mechanical Properties

| Grade | Tensile Strength (Mpa) | Yield Strength (Mpa) | Elongation % |

|---|---|---|---|

| A182 F9 | 380 | 585 | 20 |

For Alloy Steel F9 Threaded Fittings price list

Request the latest Alloy Steel F9 Threaded Fittings List. Please click on the request a quote button or click here to request the updated price list and ready stock information along with your requirement. Aashish Metal & Alloys maintains a stock of all standard items and can export them at best price for Alloy Steel F9 Screwed Fittings .

We supply of variety Alloy Steel F9 Threaded Fittings

Aashish Metal & Alloys is a Highly Acclaimed Manufacturer & suppliers of Alloy Steel F9 Threaded Forged Fittings offering all varieties in all types of Alloy Steel F9 in all sizes, with more then 52 countries worldwide.

| Alloy Steel F9 Threaded Fittings | Alloy Steel F9 Forged Threaded Fittings |

| Alloy Steel F9 High Pressure Threaded Fittings | Alloy Steel F9 Threaded 45 deg. Elbow |

| Alloy Steel F9 Screwed Fittings | Alloy Steel F9 Forged Threaded Tee |

| Alloy Steel F9 NPT Threaded Fittings | F9 Alloy Steel BSP Threaded Elbow |

| Alloy Steel F9 Threaded 45 Deg Elbow Suppliers | Alloy Steel F9 90 Degree Threaded Elbow |

| Alloy Steel F9 Threaded End Cap Dealer | Alloy Steel F9 Threaded Half Coupling Exporter |

| F9 Alloy Steel Threaded Tee Stockholder | Alloy Steel F9 Threaded Reducing Tee Distributors |

| Alloy Steel F9 Threaded Equal Cross | ANSI B16.11 Alloy Steel F9 Threaded Pipe Cap |

| Alloy Steel F9 Threaded Unequal Cross | Alloy Steel F9 High Pressure Screwed Fittings Manufacturer |

| F9 Alloy Steel Threaded Coupling | Alloy Steel F9 Threaded Reducing Couplings |

| F9 Alloy Steel Threaded Plug | F9 Alloy Steel Swage Nipple |

| DIN Alloy Steel F9 Forged Threaded Tee | DIN Alloy Steel F9 Threaded Equal Cross |

| Alloy Steel F9 Threaded Full Coupling | Stainless F9 Forged Threaded Union |

| Alloy Steel F9 Bushing | Stainless F9 Threaded Pipe Nipple |

| Alloy Steel F9 Bushing | Stainless F9 Threaded Pipe Nipple |

| F9 Alloy Steel Hex Head Bushing | Stainless F9 Hex Head Plug |

| Alloy Steel F9 Threaded Equal Tee | Alloy Steel F9 Threaded Half Coupling Stockist |

| ASTM A182 Alloy Steel F9 Threaded Boss | ASME SA182 Alloy Steel F9 Threaded Pipe Cap |

| Alloy Steel F9 Threaded Hex Plug | F9 Alloy Steel NPT Threaded Street Elbow |

Application Of Alloy Steel F9 Threaded Fittings

Application Industry

For More Information About Alloy Steel F9 Threaded Fittings please call +91-22-66362223 / 66394926 or send an email to [email protected]

Export Country

MIDDLE EAST Saudi Arabia | AFRICA Nigeria NORTH AMERICA Usa | EUROPE Russia | ASIA India SOUTH AMERICA Argentina |

Products

Special Products

PRODUCT RANGE

Please feel free to contact us. We will get back to you with 2 business days. Or just call us now.