Inconel 600 Threaded Fittings

Inconel Alloy 600 Threaded Cross, 600 Inconel Threaded Coupling, Alloy 600 Screwed Fittings, Alloy 600 Threaded Elbow, Inconel 600 Forged Threaded Tee Manufacturer in India, Nickel Alloy 600 Threaded Fittings, Alloy 600 Forged Threaded Pipe Nipple Stockist In India.

Aashish Metal & Alloys is a standard manufacturer and exporter of Inconel 600 Threaded Fittings, which is ferrite and stainless chromium and warmth resisting steel.

It is an advanced chromium ferrite warmth resistant alloy through approach of getting proper resistance to sulfidation, oxidation and different kinds of warm corrosion resistant. This specific grade is maximum commonly used within the variety of 1500 Degree F to 2100 Deg F, even though its excessive yield temperature electricity is especially low. It is the simply warmth resistant alloy in order to undergo molten copper and brass. As within the agency of different accelerated chromium ferrite stainless, Inconel Alloy UNS N06600 Threaded Bend Fittings embrittles sternly within the variety of seven-hundred Deg F to one thousand Deg F temperature.

- Inconel 600 Threaded Fittings Specifications

- Inconel 600 Threaded Fittings Equivalent Grades

- Inconel 600 Threaded Fittings Quality and Test reports

- Inconel 600 Threaded Fittings International Standards

- Related Types Of Inconel 600 Threaded Fittings

- ASTM B564 Inconel 600 Threaded Forged Fittings Dimensions Chart

- Inconel 600 Threaded Fittings Pressure Rating

- Chemical Composition

- Mechanical Properties

- Inconel 600 Threaded Fittings price list

- We supply of variety Inconel 600 Threaded Fittings

- Application Of Inconel 600 Threaded Fittings

ASTM B564 Inconel 600 Threaded 90 degree Elbow, Inconel® Alloy 600 Threaded Plug, ANSI B16.11 Inconel 600 Threaded Union, Inconel® Alloy 600 Forged Threaded Reducing Insert, 2.4816 High Pressure Threaded Fittings, Alloy 600 Threaded Pipe Cap, UNS N06600 Bushing, Alloy 600 45 Deg Threaded Elbow Suppliers in Mumbai, India.

Meanwhile, it shouldn’t be used on this specific variety of temperature, until nearly a complete lack of room temperature ductility may also possibly be abided. Sigma section embrittlement takes place upon elongated time of publicity within the temperature variety of one thousand Deg F to 1300 Deg F. It has a hovering effect of ductile-to-brittle changeover temperature. Therefore, unbeaten bending and forming is helped through low forming speeds, perimeter grounding and preheating to 250 Deg F to four hundred Deg F. Inconel Alloy DIN 2.4816 Threaded Union Fittings is more difficult to cold work than different steels due to its hovering factor of chromium content.

Meanwhile, annealing while wanted ought to be completed at 1550 Deg F to 1650 Deg F that is in addition accompanied through brief cool. It may also possibly be accomplished through conformist tactics. Post-heating and Pre-heating to three hundred Deg to six hundred Deg F is supportive. It has awesome resistance to tumbling sulphurous gases, similarly to awesome resistance to oxidation in air. It properly has awesome resistance to oil-ash corrosion and resistance to molton copper, lead and tin. Nickel-Alloy 600 Threaded Coupling may be welded with none trouble through the usage of maximum of the traditional tactics aside from oxyacetylene welding. Dissimilarities in coefficient of thermal boom of base and weld metallic needs to be taken into deliberation.

Inconel 600 Threaded Fittings Specifications

| Dimensions | ASTM B564 / ASME SB564 |

|---|---|

| Standard | ASME 16.11, MSS SP-79, 83, 95, 97, BS 3799 |

| Size | 1/8″ NB to 4″ NB Screwed-Threaded |

| Class | 2000lb/ 3000lb/ 6000lbs |

| From | 90º Elbows, 45º Elbows, Tees, Cross, Couplings, Reducers, Inserts, Caps, Nipples, Unions, Equal Tees & Reducing Tees, Plugs. |

Inconel 600 Threaded Fittings Equivalent Grades

| STANDARD | UNS | WERKSTOFF NR. | AFNOR | EN | JIS | BS | GOST | OR |

|---|---|---|---|---|---|---|---|---|

| Inconel 600 | N06600 | 2.4816 | NC15FE11M | NiCr15Fe | NCF 600 | NA 13 | МНЖМц 28-2,5-1,5 | ЭИ868 |

Inconel 600 Threaded Fittings Quality and Test reports

- Third Party Inspection

- EN 10204/3.1B

- 100% Radiography Test

- Raw Materials Certificate

- Mill test

Inconel 600 Threaded Fittings International Standards

| American Steel Threaded Fittings Standard | |

| Standard Code | Standard Name |

| ANSI ASME SA-182 | Forged fittings |

| ANSI ASME B16.11 | Socket-welding and Threaded forged fittings |

| MSS SP-79 | Socket-welding reducing Inserts |

| MSS SP-83 | Class 3000 steel socket-welding and threaded unions |

| MSS SP-95 | Swaged nipples and round plugs |

| MSS SP-97 | SW,TH and BW ends for integrally reinforced forged branch outlet |

We Supplied a Comprehensive Range Of Inconel 600 Threaded Fittings

Related Types Of Inconel 600 Threaded Fittings

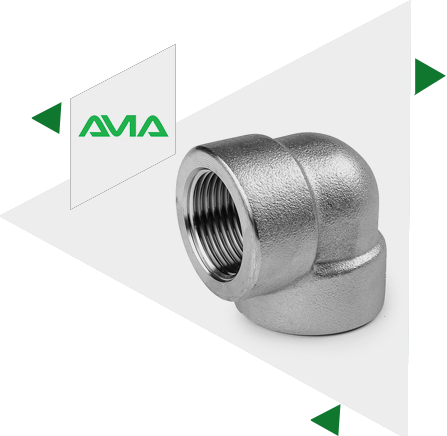

Inconel 600 Threaded Elbow

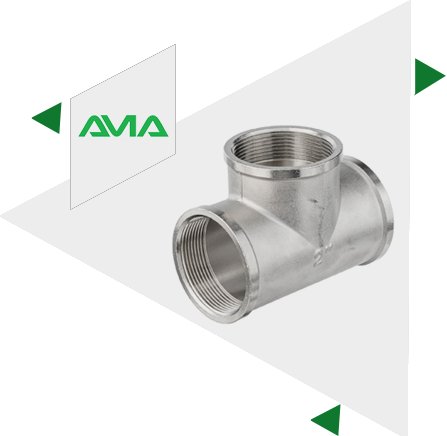

Inconel 600 Threaded Tee

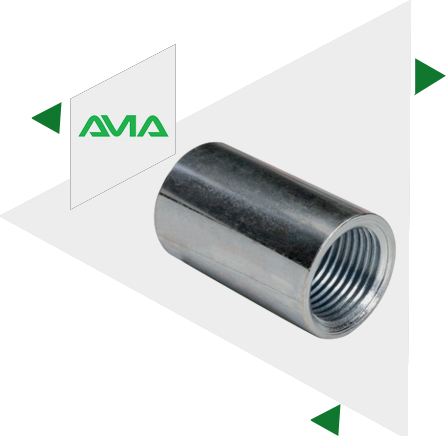

Inconel 600 Threaded Full Coupling

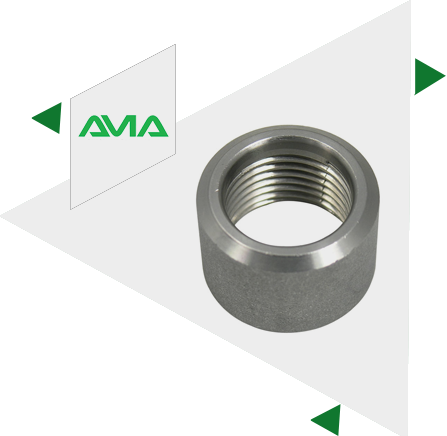

Inconel 600 Threaded Half Coupling

Inconel 600 Threaded Cross

Inconel 600 Threaded Union

Inconel 600 Threaded Pipe Cap

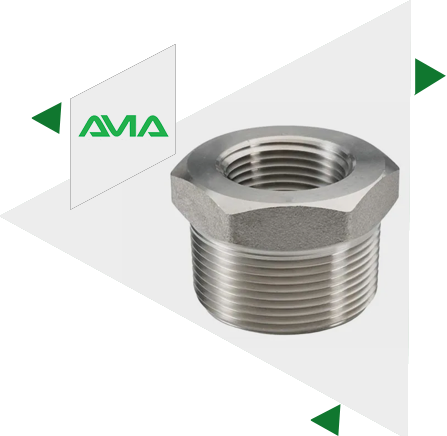

Inconel 600 Bushing

Inconel 600 Threaded Plug

Inconel 600 Threaded Hex Plug

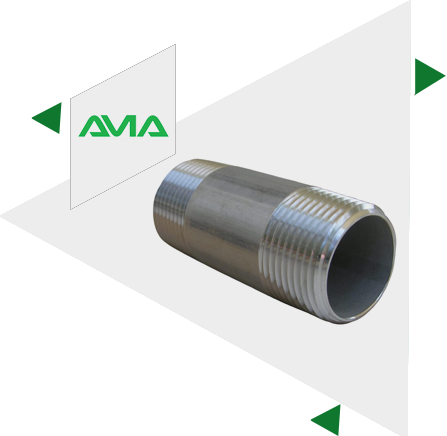

Inconel 600 Threaded Pipe Nipple

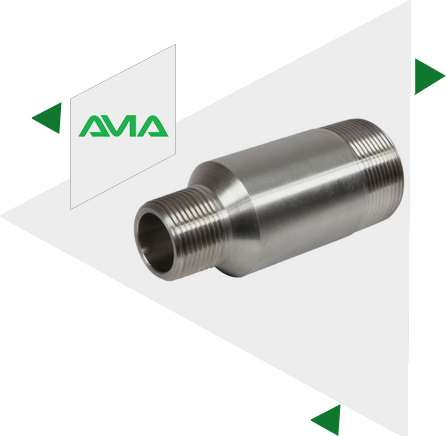

Inconel 600 Threaded Swage Nipple

ASTM B564 Inconel 600 Threaded Forged Fittings Dimensions Chart

| DN | NPS | Center to End NPT Elbow, NPT Tee, NPT Cross A |

Center to End 45 Deg Elbow C |

O.D. of Band H |

Min. Wall Thick. G |

Length of Thread. Minimum (1) |

|||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Class 2000 | Class 3000 | Class 6000 | Class 2000 | Class 3000 | Class 6000 | Class 2000 | Class 3000 | Class 6000 | Class 2000 | Class 3000 | Class 6000 | B | L2 | ||

| 6 | 1/8 | 21 | 21 | 25 | 17 | 17 | 19 | 22 | 22 | 25 | 3.18 | 3.18 | 6.35 | 6.4 | 6.7 |

| 8 | 1/4 | 21 | 25 | 28 | 17 | 19 | 22 | 22 | 25 | 33 | 3.18 | 3.30 | 6.60 | 8.1 | 10.2 |

| 10 | 3/8 | 25 | 28 | 33 | 19 | 22 | 25 | 25 | 33 | 38 | 3.18 | 3.51 | 6.98 | 9.1 | 10.4 |

| 15 | 1/2 | 28 | 33 | 38 | 22 | 25 | 28 | 33 | 38 | 46 | 3.18 | 4.09 | 8.15 | 10.9 | 13.6 |

| 20 | 3/4 | 33 | 38 | 44 | 25 | 28 | 33 | 38 | 46 | 56 | 3.18 | 4.32 | 8.53 | 12.7 | 13.9 |

| 25 | 1 | 38 | 44 | 51 | 28 | 33 | 35 | 46 | 56 | 62 | 3.68 | 4.98 | 9.93 | 14.7 | 17.3 |

| 32 | 1-1/4 | 44 | 51 | 60 | 33 | 35 | 43 | 56 | 62 | 75 | 3.89 | 5.28 | 10.59 | 17.0 | 18.0 |

| 40 | 1-1/2 | 51 | 60 | 64 | 35 | 43 | 44 | 62 | 75 | 84 | 4.01 | 5.56 | 11.07 | 17.8 | 18.4 |

| 50 | 2 | 60 | 64 | 83 | 43 | 44 | 52 | 75 | 86 | 102 | 4.27 | 7.14 | 12.09 | 19.0 | 19.2 |

| 65 | 2-1/2 | 76 | 83 | 95 | 52 | 52 | 64 | 92 | 102 | 121 | 5.61 | 7.65 | 15.29 | 23.6 | 28.9 |

| 85 | 3 | 86 | 95 | 106 | 64 | 64 | 79 | 109 | 121 | 146 | 5.99 | 8.84 | 16.64 | 25.9 | 30.5 |

| 100 | 4 | 106 | 114 | 114 | 79 | 79 | 79 | 146 | 152 | 152 | 6.55 | 11.18 | 18.67 | 27.7 | 33.0 |

| DN | NPS | End to End Couplings W |

End to End Caps P |

O.D. D | End Wall Thick. G Minimum |

Length of Thread. Minimum (1) |

||||

|---|---|---|---|---|---|---|---|---|---|---|

| Class 3000&Class 6000 | Class 3000 | Class 6000 | Class 3000 | Class 6000 | Class 3000 | Class 6000 | B | L2 | ||

| 6 | 1/8 | 32 | 19 | … | 16 | 22 | 4.8 | … | 6.4 | 6.7 |

| 8 | 1/4 | 35 | 25 | 27 | 19 | 25 | 4.8 | 6.4 | 8.1 | 10.2 |

| 10 | 3/8 | 38 | 25 | 27 | 22 | 32 | 4.8 | 6.4 | 9.1 | 10.4 |

| 15 | 1/2 | 48 | 32 | 33 | 28 | 38 | 6.4 | 7.9 | 10.9 | 13.6 |

| 20 | 3/4 | 51 | 37 | 38 | 35 | 44 | 6.4 | 7.9 | 12.7 | 13.9 |

| 25 | 1 | 60 | 41 | 43 | 44 | 57 | 9.7 | 11.2 | 14.7 | 17.3 |

| 32 | 1-1/4 | 67 | 44 | 46 | 57 | 64 | 9.7 | 11.2 | 17.0 | 18.0 |

| 40 | 1-1/2 | 79 | 44 | 48 | 64 | 76 | 11.2 | 12.7 | 17.8 | 18.4 |

| 50 | 2 | 86 | 48 | 51 | 76 | 92 | 12.7 | 15.7 | 19.0 | 19.2 |

| 65 | 2-1/2 | 92 | 60 | 64 | 92 | 108 | 15.7 | 19.0 | 23.6 | 28.9 |

| 80 | 3 | 108 | 65 | 68 | 108 | 127 | 19.0 | 22.4 | 25.9 | 30.5 |

| 100 | 4 | 121 | 68 | 75 | 140 | 159 | 22.4 | 28.4 | 27.7 | 33.0 |

Inconel 600 Threaded Fittings Pressure Rating

| ASME B16.11 Pressure-Temperature | |||||

|---|---|---|---|---|---|

| Temperature | Class | ||||

| 150 | 300 | ||||

| 1/4 – 1 inch. | 1 1/4 – 2 inch. | 2 1/2 – 3 inch. | |||

| (oF) | (oC) | ||||

| -20 to 150 | -29 to 66 | 300 | 2000 | 1500 | 1000 |

| 200 | 93 | 265 | 1785 | 1350 | 910 |

| 250 | 121 | 225 | 1575 | 1200 | 825 |

| 300 | 149 | 185 | 1360 | 1050 | 735 |

| 350 | 177 | 150 | 1150 | 900 | 650 |

| 400 | 204 | – | 935 | 750 | 560 |

| 450 | 232 | – | 725 | 600 | 475 |

| 500 | 260 | – | 510 | 450 | 385 |

| 550 | 288 | – | 300 | 300 | 300 |

We Keep Bulk Stock Of Inconel 600 Forged Threaded Fittings At Our Stockyard, Contact Us For Free Sample & Stock List.

Chemical Composition

| Grade | C | Mn | Si | S | Cu | Fe | Ni | Cr |

|---|---|---|---|---|---|---|---|---|

| 600 | 0.15 | 1.00 | 0.50 | 0.015 | 0.50 | 6.00 – 10.0 | 72.00 | 14.00 – 17.00 |

Mechanical Properties

| Element | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

|---|---|---|---|---|---|

| 600 | 8.47 g/cm3 | 1413 °C (2580 °F) | Psi – 45,000 , MPa – 310 | Psi – 95,000 , MPa -655 | 40 % |

For Inconel 600 Threaded Fittings price list

Request the latest Inconel 600 Threaded Fittings List. Please click on the request a quote button or click here to request the updated price list and ready stock information along with your requirement. Aashish Metal & Alloys maintains a stock of all standard items and can export them at best price for 600 Inconel Screwed Fittings .

We supply of variety Inconel 600 Threaded Fittings

Aashish Metal & Alloys is a Highly Acclaimed Manufacturer & suppliers of Inconel 600 Threaded Forged Fittings offering all varieties in all types of 600 Inconel in all sizes, with more then 52 countries worldwide.

| Inconel 600 Threaded Fittings | Inconel 600 Forged Threaded Fittings |

| Alloy 600 High Pressure Threaded Fittings | Inconel 600 Threaded 45 deg. Elbow |

| UNS N06600 Screwed Fittings | Inconel 600 Forged Threaded Tee |

| Inconel 600 NPT Threaded Fittings | Inconel® Alloy 600 BSP Threaded Elbow |

| Alloy 600 Threaded 45 Deg Elbow Suppliers | Inconel 600 90 Degree Threaded Elbow |

| Inconel 600 Threaded End Cap Dealer | Inconel® Alloy 600 Threaded Half Coupling Exporter |

| Inconel Alloy 600 Threaded Tee Stockholder | Alloy 600 Threaded Reducing Tee Distributors |

| Inconel® Alloy 600 Threaded Equal Cross | ANSI B16.11 Inconel 600 Threaded Pipe Cap |

| Inconel® Alloy 600 Threaded Unequal Cross | Alloy 600 High Pressure Screwed Fittings Manufacturer |

| 600 Inconel Threaded Coupling | Alloy 600 Threaded Reducing Couplings |

| Inconel® Alloy 600 Threaded Plug | 600 Inconel Swage Nipple |

| DIN 2.4816 Forged Threaded Tee | Nickel Alloy 600 Threaded Equal Cross |

| Inconel 600 Threaded Full Coupling | Inconel® Alloy 600 Forged Threaded Union |

| Inconel 600 Bushing | Alloy 600 Threaded Pipe Nipple |

| Inconel 600 Bushing | Inconel Alloy 600 Threaded Pipe Nipple |

| Alloy 600 Hex Head Bushing | Inconel® Alloy 600 Hex Head Plug |

| Alloy 600 Threaded Equal Tee | Inconel 600 Threaded Half Coupling Stockist |

| ASTM B564 Inconel 600 Threaded Boss | ASME SB564 Alloy 600 Threaded Pipe Cap |

| Inconel® Alloy 600 Threaded Hex Plug | Inconel® Alloy 600 NPT Threaded Street Elbow |

Application Of Inconel 600 Threaded Fittings

Application Industry

For More Information About Inconel 600 Threaded Fittings please call +91-22-66362223 / 66394926 or send an email to [email protected]

Export Country

MIDDLE EAST Saudi Arabia | AFRICA Nigeria NORTH AMERICA Usa | EUROPE Russia | ASIA India SOUTH AMERICA Argentina |

Products

- Stainless Steel

- Duplex & Super Duplex

- Nickel Alloy

- Monel

- Inconel

- Hastelloy

- Alloy 20

- Titanium

- Copper Nickel

- Alloy Steel

- Carbon Steel

- Beryllium Copper

- Bimetal

Special Products

PRODUCT RANGE

Please feel free to contact us. We will get back to you with 2 business days. Or just call us now.