Stainless Steel 310 Needle Valve

STAINLESS STEEL 310 ROUND BODY NEEDLE VALVE, SS 310 NEEDLE VALVE, STAINLESS STEEL 310 FLANGED NEEDLE VALVES, SS 310 INDUSTRIAL NEEDLE VALVE MANUFACTURER IN INDIA, 310 SS ANGLE NEEDLE VALVE STOCKIST IN INDIA.

Aashish Metal & Alloys is a renowned supplier and distributor of SS 310 Needle Valves, which has first rate resistance to each decreasing and oxidizing media.

It shows first rate resistance to corrosive assault with the aid of using seawater below stagnant and flowing conditions. At increased temperatures, the excessive chromium degree enables it face up to oxidation, carburization, and sulfidation. Since its far nickel-base, Stainless Steel UNS S31000 Needle Valves resists excessive temperature assault with the aid of using halides (e.g., chlorides and fluorides). With those attributes, the alloy is broadly used to guard metallic tubes and different additives in coal-fired and waste-to-electricity boilers. High content material of chromium offers it right resistance to moist corrosion with the aid of using oxidizing media (e.g., nitric acid and ferric and cupric salts).

- Stainless Steel 310 Needle Valves Specifications

- Stainless Steel 310 Needle Valves Equivalent Grades

- Stainless Steel 310 Needle Valves Quality and Test reports

- Related Types Of Stainless Steel 310 Needle Valves

- SS 310 Needle Valves Dimension

- SS 310 Female X Female Needle Valve Dimensions

- Dimensions Schedule SS 310 Male X Female Needle Valve

- 310 SS Male X Male Needle Valve Dimensions Chart

- Chemical Composition

- Mechanical Properties

- Stainless Steel 310 Needle Valves price list

- We supply of variety SS 310 Needle Valves

- Application Of SS 310 Needle Valves

UNS S31000 Integral Bonnet Needle Valve, 310 SS Forged Needle Valve, DIN 1.4841 Hydraulic Needle Valve, 310 SS High Pressure Needle Valve, SS 310 Union Bonnet Needle Valve, SS 310 Compression Needle Valve, 310 Stainless Steel Needle Control Valve, SS 310 Needle Valve Suppliers in Mumbai, India.

Contents of molybdenum and tungsten deliver the alloy resistance to moist decreasing media (e.g., sulfuric and hydrochloric acids). It need to now no longer be utilized in carrier temperatures above 1250° F because of the formation of adverse stages which shape above this temperature. It additionally has first rate resistance to oxidizing aqueous media. Stainless Steel WNR. 1.4841 Needle Valves has notable resistance to a huge sort of chemical method environments which include robust oxidizers consisting of ferric acids, acetic anhydride, and seawater and brine solutions. They are also generally used for chemical processing applications.

They are used for several applications consisting of in pharmaceutical industries use alloy and tubing to keep away from infection because of corrosion associated failures. They also are utilized in Chlorination systems, Pesticide production, Incineration scrubber systems, Waste water processing, and more. It became decided on for this software after significant trying out within the real bleach washing machine environment. It has higher corrosion resistance than the original material and higher than the following candidate. It is an alloy supposed for excessive temperature use in company of the right corrosion resistance. 310 Stainless Steel Needle Valves is machinable with the aid of using traditional strategies and are easily fashioned by means of having the aid of using traditional methods.

Stainless Steel 310 Needle Valves Specifications

| Size | 1/4″ to 1″ (Female / Female BSP and BSPT), 3/8″ to 1″ (Female / Female NPT) and 1/4″ to 1/2″ (Male / Female BSPP). |

| Thread | NPT, BSPP, BSPT, JIC, METRIC, UNF |

| Connection | Threaded, Tube End, Butt Weld, Socket Weld, Weld Nipple, Flanged, Sae |

| Function | 2 Way, 3 Way |

| Pressure Rating | 1500 PSI, 3000 PSI, 6000 PSI, 10000 PSI, 15,000 PSI, 20000 PSI |

| Orifice Size | 2 MM TO 9.5 MM |

| Standard | ISO , DIN , ANSI , API , ASME , AWWA , MSS |

| Design | Forged Body with Inline/Straight or Angle Pattern, Integral Bonnet Design |

| Patterns | Straight / Angle |

| Needle Valve Type | Bar Stock Needle Valve, High Pressure Needle Valve, Angle Needle Valve, Union Bonnet High Pressure Female X-Female NPT, Miniature Needle Valve, Screwed Bonnet Needle Valve, Forged Needle Valve |

| Maximum Working Pressure | Up to 6000 psig (413 bar) |

| Equivalent Brands | Swagelok, Parker, Dk-Lok, Hamlet, Oliver Valves, Hoke |

Stainless Steel 310 Needle Valves Equivalent Grades

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

|---|---|---|---|---|---|---|---|

| SS 310 | 1.4841 | S31000 | SUS 310 | 310S24 | 20Ch25N20S2 | – | X15CrNi25-20 |

Stainless Steel 310 Needle Valves Quality and Test reports

- Third Party Inspection

- Radiography Test

- Hydrostatic Shell Test

- Pneumatic Seat Test

- Pitting Resistance Test

- Hydrostatic Test

We Supplied a Comprehensive Range Of 310 Stainless Steel Needle Valves

Related Types Of Stainless Steel 310 Needle Valves

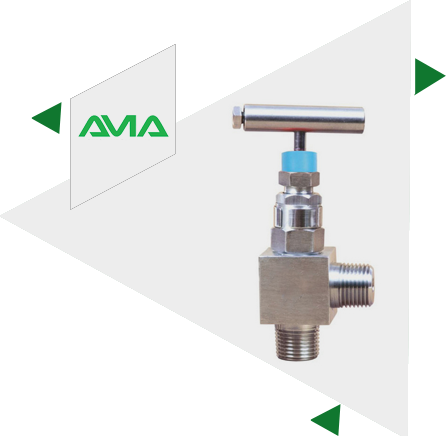

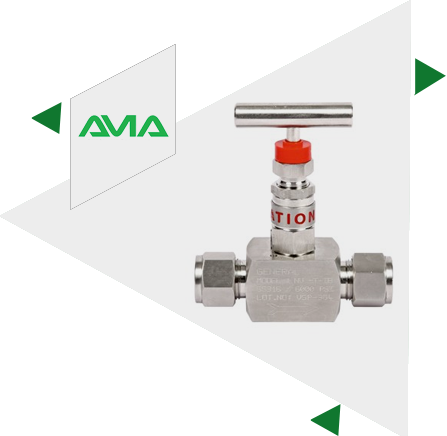

SS 310 Angle Needle Valve

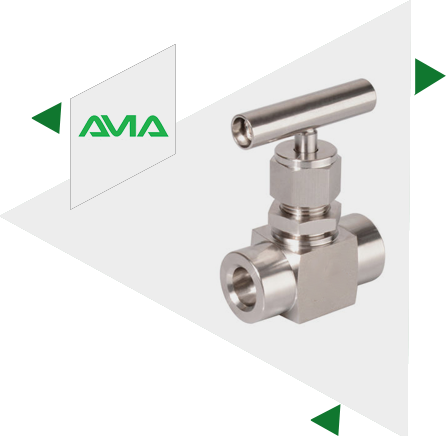

SS 310 Union Bonnet Needle Valve

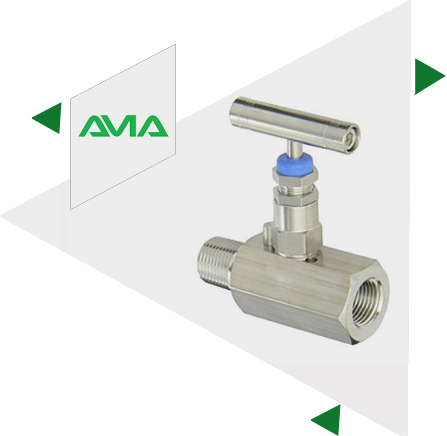

SS 310 Forged Needle Valve

SS 310 Screwed End Needle Valve

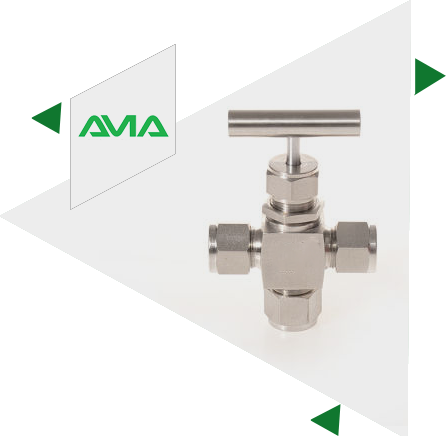

SS 310 Tube End Needle Valve

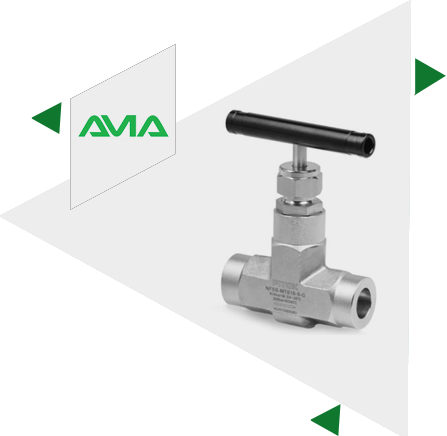

SS 310 Socket Weld Needle Valve

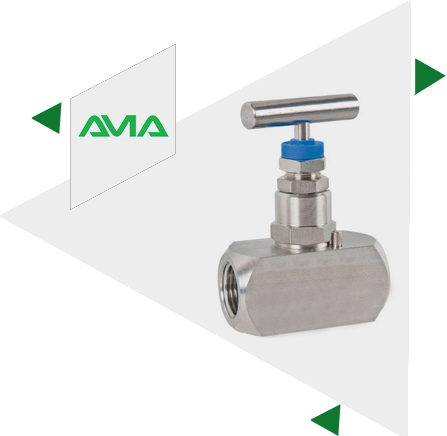

SS 310 Hex Body Needle Valve

SS 310 3 Way Needle Valve

SS 310 Panel Mounted Needle Valve

SS 310 Miniature Needle Valve

SS 310 Round Body Needle Valve

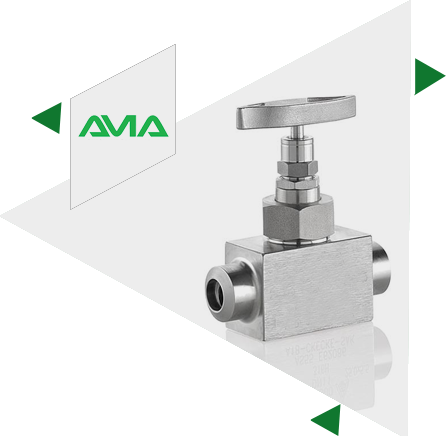

SS 310 Square Body Needle Valve

SS 310 Needle Valves Dimensions

| Size | L | a | b | W | H |

|---|---|---|---|---|---|

| 1/8″ | 56 | 28 | 28 | 60 | 80 |

| ¼” | 56 | 28 | 28 | 60 | 80 |

| 3/8” | 56 | 28 | 28 | 60 | 80 |

| ½” | 58 | 28 | 28 | 60 | 81 |

| ¾” | 62 | 35 | 35 | 60 | 85 |

| 1” | 70 | 45 | 45 | 70 | 100 |

| Port Size (BSP) | Media Pressure | Media Temperature | CV |

|---|---|---|---|

| 1/8″ | 0 to 408 Bar | -20°C to 230°C | |

| ¼” | 0 to 408 Bar | -20°C to 230°C | 0.4 |

| 3/8” | 0 to 408 Bar | -20°C to 230°C | 0.4 |

| ½” | 0 to 408 Bar | -20°C to 230°C | 0.6 |

| ¾” | 0 to 408 Bar | -20°C to 230°C | 1.6 |

| 1” | 0 to 408 Bar | -20°C to 230°C | 2.5 |

Female X Female Needle Valve Dimensions

| Size | A | B | ±C | D |

|---|---|---|---|---|

| 1/8″ | 19 | 50 | 65 | 45 |

| 1/4″ | 22 | 50 | 70 | 50 |

| 3/8″ | 25 | 55 | 75 | 55 |

| 1/2″ | 30 | 65 | 85 | 55 |

| 3/4″ | 36 | 75 | 95 | 65 |

| 1″ | 40 | 85 | 100 | 65 |

| 1-1/4″ | 54 | 90 | 120 | 80 |

| 1-1/2″ | 62 | 110 | 130 | 88 |

| 2 | 72 | 120 | 150 | 95 |

Dimensions Schedule Male X Female Needle Valve

| Size | A | B | ±C | D |

|---|---|---|---|---|

| 1/8″ | 19 | 50 | 65 | 45 |

| 1/4″ | 22 | 50 | 70 | 50 |

| 3/8″ | 25 | 55 | 75 | 55 |

| 1/2″ | 30 | 65 | 85 | 55 |

| 3/4″ | 36 | 75 | 95 | 65 |

| 1″ | 40 | 85 | 100 | 65 |

| 1-1/4″ | 54 | 90 | 120 | 80 |

| 1-1/2″ | 62 | 110 | 130 | 88 |

| 2 | 72 | 120 | 150 | 95 |

Male X Male Needle Valve Dimensions Chart

| Size | A | B | ±C | D |

|---|---|---|---|---|

| 1/8″ | 19 | 50 | 65 | 45 |

| 1/4″ | 22 | 50 | 70 | 50 |

| 3/8″ | 25 | 55 | 75 | 55 |

| 1/2″ | 30 | 65 | 85 | 55 |

| 3/4″ | 36 | 75 | 95 | 65 |

| 1″ | 40 | 85 | 100 | 65 |

| 1-1/4″ | 54 | 90 | 120 | 80 |

| 1-1/2″ | 62 | 110 | 130 | 88 |

| 2 | 72 | 120 | 150 | 95 |

We Keep Bulk Stock Of 310 Stainless Steel Needle Valves At Our Stockyard, Contact Us For Free Sample & Stock List.

Chemical Composition

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | Fe |

|---|---|---|---|---|---|---|---|---|---|

| SS 310 | 0.015 max | 2.0 max | 0.15 max | 0.020 max | 0.015 max | 24.00 – 26.00 | 0.10 max | 19.00 – 21.00 | 54.7 min |

Mechanical Properties

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

|---|---|---|---|---|

| 7.9 g/cm3 | 1402 °C (2555 °F) | Psi – 75000 , MPa – 515 | Psi – 30000 , MPa – 205 | 40 % |

Stainless Steel 310 Needle Valves price list

Request the latest Stainless Steel 310 Needle Valves List. Please click on the request a quote button or click here to request the updated price list and ready stock information along with your requirement. Aashish Metal & Alloys maintains a stock of all standard items and can export them at best price for 310 Stainless Steel Needle Valves.

We supply of variety SS 310 Needle Valves

Aashish Metal & Alloys is a Highly Acclaimed Manufacturer & suppliers of Stainless Steel 310 Needle Valves offering all varieties in all types of 310 Stainless Steel in all sizes, with more then 52 countries worldwide.

| Stainless Steel 310 Male Needle Valve | Stainless 310 Body Needle Valves |

| Stainless Steel 310 Pneumatic Needle Valve | Stainless 310 TMulti-Port & Gauge Needle valve |

| 310 Stainless Steel Tube End Needle Valve | SS 310 Socket Weld Needle Valve |

| SS 310 Compression Needle Valve Dealer | SS 310 Hydraulic Needle Valve Exporter |

| 310 SS Miniature Needle Valve Stockholder | SS 310 Forged Needle Valve Distributors |

| SS 310 Hex Needle Valve | 310 Stainless Steel Panel Mount Needle Valve |

| Stainless Steel 310 Water Flow Control Needle Valve | 310 SS High Temperature Needle Valve |

| SS 310 Integral Bonnet Needle Valve Suppliers | 1/4 Stainless Steel 310 Needle Valve |

| NPT Thread Stainless Steel 310 Needle Valve | Stainless Steel 310 Flow Control Needle Valves |

| UNS S31000 Flanged Needle Valves | Stainless Steel 310 Needle Control Valve |

| SS 310 Female Thread Needle Valve | Stainless Steel 310 Angle Needle Valve |

| 310 SS 3 Way Needle Valve | 310 SS Panel Mounted Needle Valve |

| UNS S31000 Union Bonnet Needle Valve | SS 310 Screwed End Needle Valve Manufacturer |

| 310 SS 3000 PSI Instrumentation Needle Valve | SS 310 6000 PSI Needle Valve |

| DIN 1.4841 Needle Valve | 1½” Stainless Steel 310 Square Body Needle Valve |

| Stainless Steel 310 Needle Valves | SS 310 Instrumentation Needle Valve |

| SS 310 High Pressure Square Body NPT Thread Needle Valve | Stainless Steel 310 Round Body Needle Valve |

| 310 SS Female Thread Needle Valve | SS 310 Square Body Needle Valves Stockist |

Application Of SS 310 Needle Valves

Application Industry

For More Information About Stainless Steel 310 Needle Valves please call +91-22-66362223 / 66394926 or send an email to [email protected]

Export Country

MIDDLE EAST Saudi Arabia | AFRICA Nigeria NORTH AMERICA Usa | EUROPE Russia | ASIA India SOUTH AMERICA Argentina |

Products

- Stainless Steel

- Duplex & Super Duplex

- Nickel Alloy

- Monel

- Inconel

- Hastelloy

- Alloy 20

- Titanium

- Copper Nickel

- Alloy Steel

- Carbon Steel

- Beryllium Copper

- Bimetal

Special Products

PRODUCT RANGE

Please feel free to contact us. We will get back to you with 2 business days. Or just call us now.